How do Solar Photovoltaic Systems actually work?

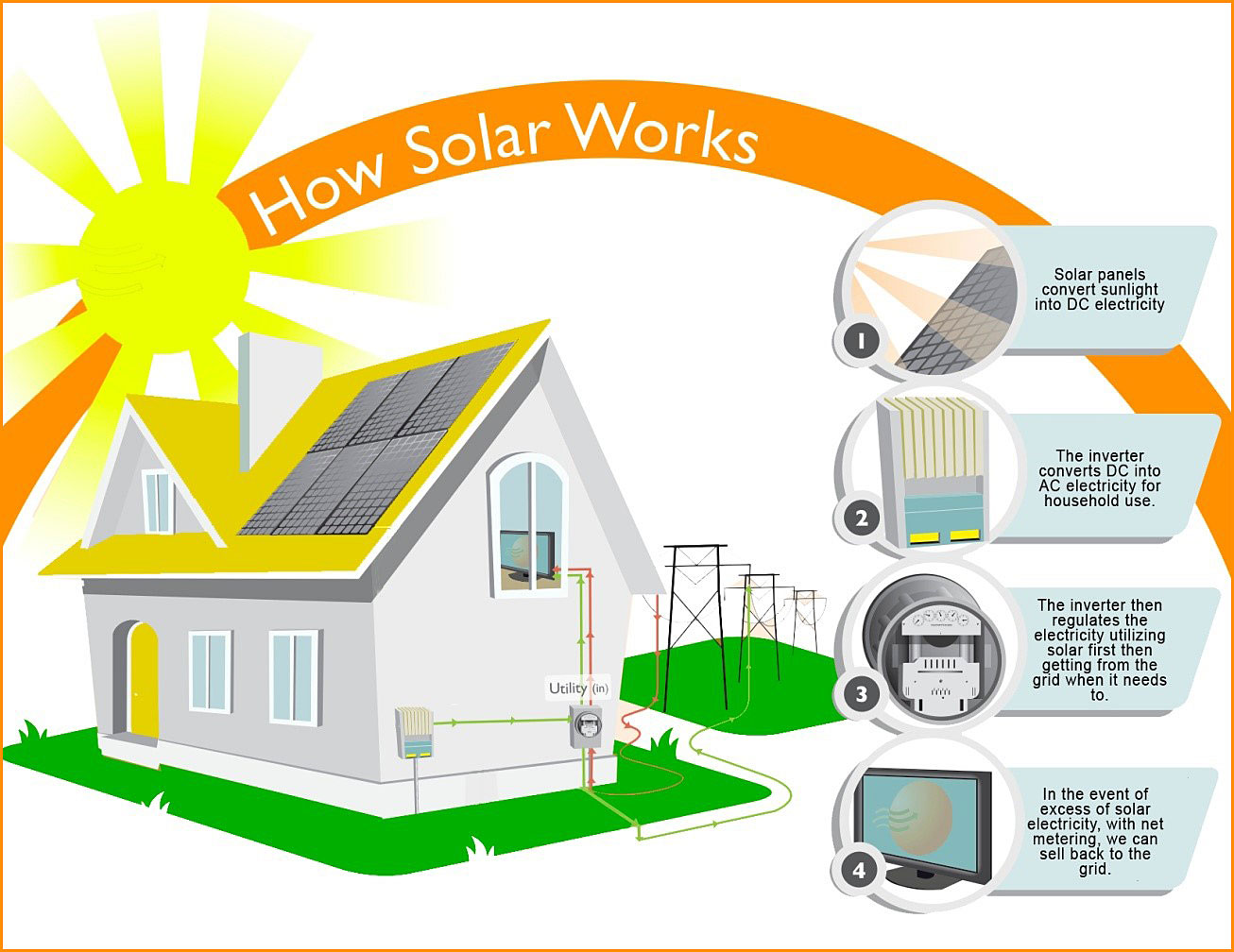

To have a simple understanding of solar electricity systems, follow the step-by-step diagram below.

- The solar panels on the roof collect energy rays from the sun and convert it into DC electricity.

- The solar panels then send this DC electricity to an inverter. This electricity is then converted into AC current for consumption by the household.

- The electricity is then sent to the service panel of the house for distribution into the household’s electrical system. If the solar system does not produce enough energy to meet the household’s demand, power will be consumed from the grid.

- If the solar system produces more than the demand of the household, the excess energy will distribute back to the grid. In some instances with net metering or buyback programs, we can monitor the system and receive credits on your electricity bill.

Are there more characteristics of this process?…

Of course, but in a nutshell this is how about 95% of solar PV systems work. Other solar systems may become more complicated with applications of batteries, wind power generators, and gas power generators.

Different Types of Solar Panels

Your main choices of panel types for Solar PV are Mono-crystalline Silicon, Poly-crystalline Silicon, and Thin Film. There are other technologies, but TAC focuses extensively on these 3 types for cost and availability benefits.

Silicon Crystal modules are the most common solar technology. They are everywhere from street signs, gate entries, to on top of roofs. This is because it is the oldest and most efficient type of technology available to us. Thin film modules are the same type of technology used to power personal calculators. Now thin film panels are used for utility size projects.

So What Are The Differences?…

The video to the right explains the differences in Mono and Poly-Crystalline panels.

Thin film is an extremely thin sheet of silicon, usually made with plasma, that can be molded into whatever shape is needed. This technology does not use soldering joints, so in theory it has less possibilities for failure. Thin film is a cheaper alternative to silicon crystals, but at the same time it is much less efficient. This technology is thus used for systems that have unlimited space, thus why it is used for utility grade systems. Because of the mold ability that Thin Film possesses, it is also used in building integrated solar systems.

INVERTERS

There are 3 main types of inverters used in residential and light commercial: String Inverter, Micro-Inverter, and Power Optimizers. Each one has its benefits and disadvantages. Below you will find information about the inverters that TAC installs.

String Inverters

These are the most common inverters across America and Europe. They were the first types of inverters developed and owned the market share in the past. To install central string inverters, the solar panels have to be connected in a daisy chain string and then wired down to the inverter. One of the biggest disadvantages of using a string inverter for residential systems is shading. Many homes have trees, chimneys, roof stacks, or other obstructions around them that shade the roof. When one module is shaded just a bit, it can bring down that string by 50% very easily. If shaded enough, that string can be completely shutdown even if all the other modules have full sun. This becomes a huge complication for designers of the systems.

These are the most common inverters across America and Europe. They were the first types of inverters developed and owned the market share in the past. To install central string inverters, the solar panels have to be connected in a daisy chain string and then wired down to the inverter. One of the biggest disadvantages of using a string inverter for residential systems is shading. Many homes have trees, chimneys, roof stacks, or other obstructions around them that shade the roof. When one module is shaded just a bit, it can bring down that string by 50% very easily. If shaded enough, that string can be completely shutdown even if all the other modules have full sun. This becomes a huge complication for designers of the systems.

New code regulations have also hindered the central inverter technology as various AHJs have enforced the need for added equipment. This code compliant equipment, called Rapid Shutdown, is extremely costly and thus drives more contractors to installing other types of inverters.

Most common brands of central string inverters are SMA, Fronius, Schneider Electric, Kaco, and Power One.

Micro-Inverters

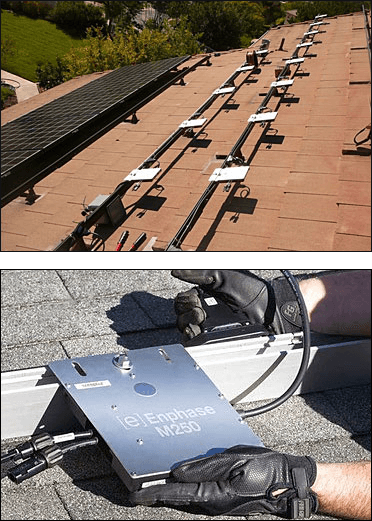

Micro-Inverters have become the new standard in residential PV with Enphase being the main manufacturer installed. This technology allows for each individual module to have its own inverter. What this does is allows for complete design freedom for constructing solar systems.

Micro-Inverters have become the new standard in residential PV with Enphase being the main manufacturer installed. This technology allows for each individual module to have its own inverter. What this does is allows for complete design freedom for constructing solar systems.

One of the main advantages of this component is shading no longer becomes such a problem. If you have a circuit of 10 modules, and one module gets shaded, only that module is affected. The other nine panels that have full sun will operate at maximum. A consumer no longer has to worry about the “weakest link” bringing the system down.

Another advantage of micro-inverters are that they do not require Rapid Shutdown equipment, so contractors have an easier time installing them. The warranty on Enphase micro-inverters is also extremely better than its string inverter counterparts. Where string inverters usually carry a 10-12 year warranty, Enphase carries a 25 year warranty.

The main disadvantage of micro-inverters are the cost. They are the most expensive type of inverters and are not recommended for commercial applications where a string inverter would have the same effect.

Power Optimizers

Power Optimizers basically take the best of both worlds from the string inverters and the micro inverters. In a system, each module would connect to its own individual power optimizer just like a micro-inverter. The power optimizer does not actually change the electricity over from DC to AC though, instead it regulates that voltage for optimum performance for harvesting more energy from each module. After power passes through the optimizer, it is then transferred to the inverter on the wall where it converts it to AC power.

The most popular manufacturers of these is the SolarEdge inverter. As the fastest growing inverter manufacturer in the country, more and more contractors are installing power optimizers systems. For a look on the advantages of SolarEdge, please watch the short video to the right.

Side by Side Inverter Technology Comparisons

| STRING INVERTER | MICRO INVERTER | POWER OPTIMIZER |

|---|---|---|

| Pros | Pros | Pros |

| • Most cost effective* • Great for simple systems with zero shading factors • Best fit for commercial applications | • Complete freedom with design • Great for shaded areas • Very easy installation • "Rapid Shutdown" not required* • Monitor each individual module • Easily expandable for retrofits | • Relative freedom with design • Great for shaded areas • More cost effective than Micro Inverters • Simple installations • "Rapid Shutdown" not required* • Monitor each module |

| Cons | Cons | Cons |

| • System only as strong as weakest link • Limited freedom with design capabilities • Requires "Rapid Shutdown" for most AHJs* • Not recommended for shaded areas • Limited monitoring capabilities | • Most expensive inverter technology • Not recommended for Commercial Applications | • Some retrofit complications • More cost than String Inverter* |

* “Rapid Shutdown” refers to a code compliant disconnect that is enforced in various jurisdictions. When enforced, the cost of a String Inverter system can become the most expensive technology in Residential applications.